Learning from the expert

MAYER & CIE. KNOW-HOW PANEL

We have gathered many decades of experiene in circular knitting.

In our new series “Mayer & Cie. know-how panel” we share this valuable knowledge with you. In concise presentations

we provide insights into relevant topics in circular knitting, from producing fine gauge fabrics to reducing a center crease

1. high quality fine gauge fabrics

In order to produce high quality fine gauge fabrics, it takes an adequate circular knitting machine along with premium yarn and in-depth knowledge.

Compromising on any of these aspects means compromising on fabric quality. This we call this “the fine gauge rule”. In our Know-how Panel on fine gauge fabrics, we reveal other relevant aspects to be considered.

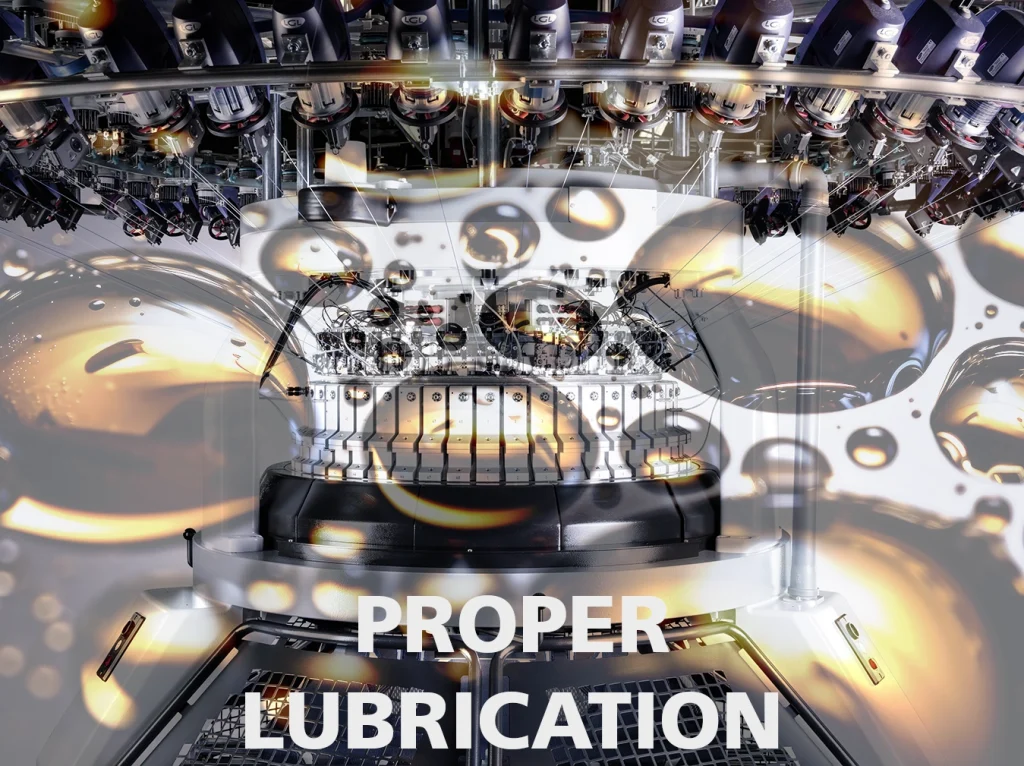

2. Optimal lubrication of a circular knitting machine

Three reasons for proper lubrication

- Optimal lubrication reduces friction between the moving parts of the machine.

This results in smooth and efficient movement. - Oil lubrication protects the parts from corrosion by forming a protective layer,

repelling other harmful substances and cleaning elements needed for stitch

formation, such as needles and sinkers. This keeps the machine in good

condition and working reliably. - Oil lubrication helps to cool the parts, especially in high-speed machines, by

dissipating the heat generated by friction. This helps to prevent overheating and possible damage.

In this presentation you will learn about the possibilities of an optimised

lubrication of your circular knitting machine.